Will Epoxy Bond To Acrylic Paint?

What is Acrylic? (PMMA) – polymethyl methacrylate – Several types of industrial adhesive bond acrylic. Because its surface is receptive to adhesive bonding, bond strength normally exceeds the actual substrate forcefulness (meaning that when the joint is pulled autonomously, the substrate breaks before the adhesive articulation). Nigh applications involve clear acrylic, so usually, a crystal articulate, non-yellowing adhesive is preferred. There are a number of industrial agglutinative options.

How to Bond Acrylic?

Cyanoacrylate – All grades attach well to acrylic. Due to acrylics susceptibility, to bond acrylic with cyanoacrylate, it is important to use cyanoacrylate adhesive sparingly. When operators try to wipe backlog agglutinative outside the joint abroad it volition fog the acrylic. Cyanoacrylates offer a rapid cure in seconds, do not crave any mixing or curing equipment. These adhesives are particularly suited to high-speed production lines. Limitations – maximum gap fill up is 0.5mm. Using alkoxy-ethyl cyanoacrylates will reduce visible powdery remainder on the surface and is less pungent than a regular ethyl cyanoacrylate.

Epoxy adhesive – single component epoxies are not suitable as the heat required to cure the adhesive will damage acrylic. However, two-component epoxies will bond acrylic. Many grades volition bond; notwithstanding, frequently clear grades such as ET500, ET515 are preferred over blackness or other opaque products.

MS Polymer – For a flexible bonding solution MS Polymers tin can be considered. Since most acrylic is clear, MS359 CLEAR will provide a good finished advent.

UV Curable adhesives. Permabond UV632, UV639, and UV645 UV/Visible low-cal cure adhesives are recommended. Many grades of acrylic are UV stabilized – which means some or all of the UV light is blocked. Consequently, the UV/Visible light cure is recommended to ensure cure. All three of these products will produce a bond which is stronger than the substrate.

Structural acrylics – several grades are available. MMA's provide very expert bond strength but are flammable and have a very strong odor. As a result, they are often non acceptable, and so Permabond formulated low odor toughened acrylic adhesives.

To determine the best specific adhesive to bond acetal in your awarding, please provide some particular to our technical team and our agglutinative advisors will become back to you with a recommendation.

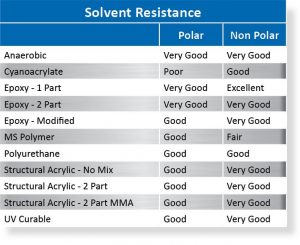

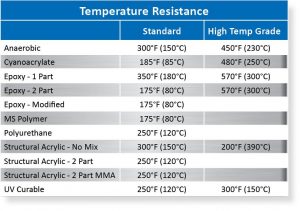

In improver to adhesion to acrylic, several other parameters are generally involved in selecting the best agglutinative. Understanding the solvent and temperature resistance of the adhesives is peculiarly relevant in selecting the all-time type of product.

Note: Products tin withstand higher temperatures for brief periods providing the joint is not disproportionately stressed.

Tips for surface preparation:

ane. Providing the surface is clean and dry and gratuitous from contamination, acrylic tin can generally be bonded "As Received".

two. Engineers often choose to do a solvent wipe before bonding or for clean up afterwards and use isopropanol or Permabond Cleaner A. Many solvents, notably acetone, are likewise ambitious and as a result, will attack the plastic.

Properties of Acrylic:

- Surface energy: 38 mJ/m²

- Maximum service temperature: 85°C

- Softening temperature: 120°C

- Coloured, opaque, transparent, clear or metalized

It seems like acrylic is constitute in every industy. A few examples of acrylic uses follow:

- Point of auction displays

- Windows and skylights

- Medical devices

- Store fitting

- Signage

- Automotive lenses and instrument panels

Source: https://www.permabond.com/materials_bonded/how-to-bond-acrylic/

Posted by: miltonthismity.blogspot.com

0 Response to "Will Epoxy Bond To Acrylic Paint?"

Post a Comment